Track’n View

Performance metrics… Data at source…

OEE

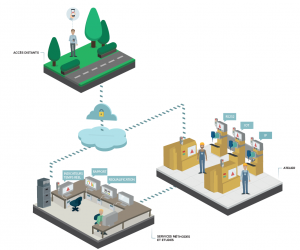

Track’n View is a software solution designed for the acquisition, use and analysis of production data. Track’n View monitors your resources and processes to generate performance metrics.

REAL-TIME CONNECTION TO MACHINES

Track’n View has an acquisition front-end that connects to PLCs, IoT, NC machines and workshop cells. Associated with operator qualification of downtime, automatic acquisition guarantees very precise status reporting.

Connects to machines to collect reliable metrics.

-

ACQUISITION

Track'nView has a communication front-end that enables real-time data to be collected at source.

-

REPORTING

Users can set report formats that can be sent by e-mail. Pareto uptime charts, standard metrics.

-

REQUALIFICATION

The direct connection to the NC machine tools still allows for human intervention to requalify causes for machine downtime.

-

LOGGING

Track'n View logs all events (machine status, transitions, statements, work orders, etc.) on-the-fly in the database, using source time-stamps.

-

Product documentation is one thing. Contact with our pre-sales team to witness a demonstration of our industrial solutions is another. Contact our services and we will show you how we communicate with equipment from a range of NC machine tool makers including NUM, FANUC and SIEMENS.